Whether you are doing remodeling work at home, working on a major project at a commercial lot, or something in between, rely on construction mats from Greatmats to make it safer to work and move around the job site. In areas where the earth is torn up and muddy – or where you want to make sure it doesn’t end up that way – our heavy-duty construction matting can support people walking or the movement of heavy equipment. We offer construction grass mats that protect your grass by creating a temporary road for moving equipment. Golf courses, schools, parks, cemeteries, tree-trimming companies, and homeowners can all take advantage of these plastic ground protection mats. Don’t risk torn-up turf or lasting ruts on your property during work involving heavy equipment and vehicles – let our experts at Greatmats help you find the perfect product to protect your property!

Article Library

Video Library

Ideas Before You Buy Construction Mats

Tips & considerations for purchasing Construction Mats:

The following blogs offer tips on what aspects to look for in construction mats before making a purchase. Wherever you plan to use this flooring, these are all important things to learn before making your final decision.- Construction sites can become a muddy mess in a hurry when workers drive heavy machinery across a lawn or bare ground. You need mats that can support the weight of vehicles without sinking or buckling. Learn More: What Are the Best Mud Mats for Construction Sites?

- When construction workers must move from dirty areas outdoors to clean areas inside the building, using tacky walk-off floor mats catches the dirt and dust, keeping your indoor floors cleaner than using traditional scrape-off floor mats. Learn More: When Should You Use Sticky Floor Mats on a Construction Site?

- Finding the right size of construction mat to use depends on whether you need to create walkway access, a temporary road for vehicles, or something in between. Greatmats carries many sizes and widths of mats for construction projects. Learn More: What Size of Ground Protection Mat Do I Need?

Top 10 Questions About Construction Mats

Below are the most popular questions we've received about construction mats. Click the question to get a detailed answer and explanation on these topics.- How Versatile Are Ground Protection Mats? You can use ground protection mats in a variety of locations around a building site, home, or rural area. They can support the weight of almost any size of heavy-duty construction vehicle.

- How Does an Erosion Control Grid Work? Erosion control tiles are usable in any area where you want to protect the ground from washing away. These tiles consist of open grids where installers can pour dirt or gravel into the holes to hold the ground in place.

- Why Do You Need Outrigger Pads? Heavy equipment parked in place during usage can become unstable on soft ground and may tilt or topple. Outrigger pads give the equipment a sturdy base when it’s under significant stress, such as occurs with a crane or backhoe.

- What Should You Know About Access Mats and Where Should You Use Them? Understandably, most people don’t work with ground protection mats every day and may be unfamiliar with the benefits they provide. These mats consist of dense plastic and don’t sink into the ground when driving heavy vehicles over them. They can support many tons of weight.

- How Do You Protect Lawns From Heavy Equipment With Ground Protection Mats? To protect a lawn from damage when driving heavy equipment across it to a build site, just lay the protection mats end to end as a temporary road. Lay them in all the areas where the wheels or tracks will make contact with the ground.

- How Do You Make a Temporary Walkway or Sidewalk Over Mud or Grass? To make a sidewalk over mud or grass, lay ground protection mats end to end or side by side in the area where you want people to be able to move safely. These mats will not sink into the ground as people walk across them.

- How Do I Protect My Driveway From Heavy Objects? When driving large equipment across a concrete driveway, cracks or breakage could occur. By laying protection mats across the concrete, it supports the weight of the equipment, protecting the concrete from damage.

- How Do You Clean Ground Protection Mats? To clean ground protection mats, you can use a garden hose with a sprayer or a pressure washer. For stubborn mud or debris, you can use a scrub brush on the durable plastic without damaging it.

- How Do You Create a Temporary Road Using Mats? To create a temporary road using ground protection construction mats, lay them end to end to match the path of the tires or tracks of the machine. Select a product that can support the weight of the heaviest vehicle that will use the temporary road.

- What Are the Top Uses for Ground Protection Mats? The top uses for ground protection mats include preventing ruts from forming in grass or dirt as heavy construction vehicles drive across the property. They can also protect driveway or sidewalk concrete from cracking or breaking when heavy vehicles drive across it.

Best Construction Mat Products

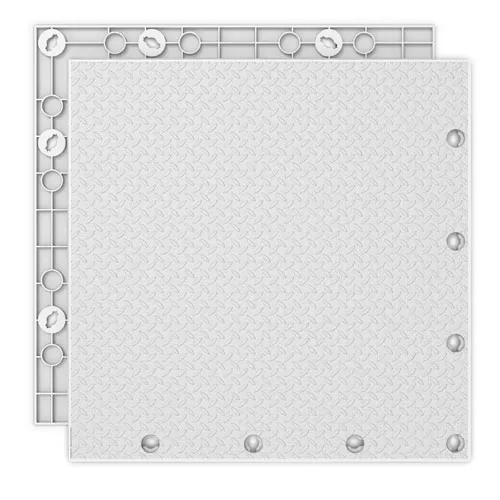

Gmats Ground Protection Mats, 1/2 Inch x 4x8 Ft.

The Gmats Ground Protection Mats provide support and traction for vehicles as they move across soft ground. These polyethylene plastic mats are made in the United States and can support 90 tons each.

Blue Gator Ground Protection Diamond Mats, 1/2 Inch x 3x8 Ft.

Our Blue Gator Ground Protection Diamond Mats offer a reversible design with a “V” traction pattern on one side and a diamond traction pattern on the other side. It’s a Made in the USA product that can support up to 70 tons of vehicular weight.

Matrax Heavy Duty Drivable Composite Mats, 1.5 Inch x 3.89 x 3.89 Ft.

When you need an even load transfer between panels, our Matrax Heavy Duty Drivable Composite Mats deliver this key feature. These Made in the USA panels interlock, making them ideal for use as event flooring when you need to protect the grass or artificial turf underneath.

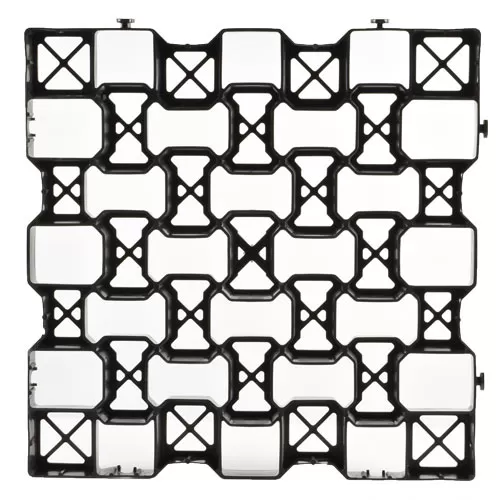

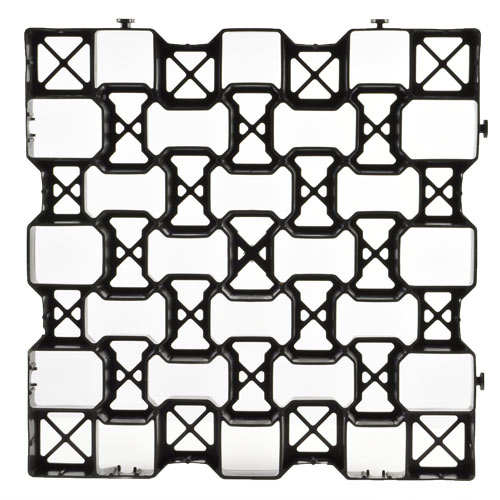

GeoGrid Cellular Paving System Tiles, 4 cm x 1.6x1.6 Ft.

If you have areas on your property subject to erosion because of flooding or poor drainage, our GeoGrid Cellular Paving System Tiles provide reinforcement and stabilization of the ground. Connect these tiles along the area that’s subject to erosion and fill the open holes in the grid design with dirt or gravel to secure them in place.

Outrigger Pads, 3/4 Inch x 15x15 Inches

To support the weight of stationary large vehicles and to keep crew members safe, trust our Outrigger Pads. They can support up to 55,000 pounds of vertical load capacity for the extended outrigger arms of a crane, lift bucket, or utility truck.

TackyMat, 24x36 Inches

Our TackyMat product pulls dust and other debris from the shoes of people moving from a construction area into a home or building, keeping the interior cleaner. Each product has 120 removable sheets, and you can discard each sheet as it becomes soiled, revealing a fresh tacky sheet.

Construction Mat Customer Installations

Axel Landscape

Greatmats customer Axel Landscape needed mats to protect clients’ lawns from the skid steers and track loaders the workers use to move dirt, trees, gravel, and rolls of sod. Our mats allow for a temporary road that protects the property during the length of the project.

Lawn Protection Mats Clear Ground Protection Mats

Lisk Landscape Innovations

Lisk Landscape Innovations needed a type of mat to protect clients’ yards from heavy equipment, but that also would allow sunlight to penetrate the mat and reach the grass during a longer temporary installation. Our Greatmats team suggested our transparent plastic mats, which worked perfectly to help the grass survive while the mats were in place.

Yard Protection Mats: Clear Ground Protection Mats

Whispering Tree Service

When moving heavy equipment into place to work on tree trimming or stump grinding, wet conditions on some days would leave Whispering Tree Service unable to work for fear of damaging customer lawns. Protection mats from Greatmats supported the equipment’s weight without causing damage, delivering the perfect results.

Grass Protection Mats: AlturnaMats Ground Protection Mats

Construction Mats Installation & Maintenance Videos

How to Install 4x8 Ground Protection Mats for Driving on Mud

How to Clean Ground Protection Mats

How to Install Matrax Composite Mats - Light & Heavy Duty