Options for 3x3 Rubber Floor Tiles

Square rubber mats are a great choice for their durability, anti-fatigue properties, and ease of maintenance. At Greatmats, we offer a variety of sizes in rubber gym floor tiles, including 3x3 rubber floor tiles. When you want to cover a larger space at a fitness center or gymnasium in a shorter time, our 3x3 interlocking rubber mats can make the installation job go faster compared to smaller mats. Our 3ft x 3ft mats each cover 9 square feet, while 2ft x 2ft mats only cover 4 square feet apiece.

Types of 3x3 Gym Floor Mats

At Greatmats, we offer a few different formats and types of gym floor mats, helping you match the design with the usage plans you have for them.

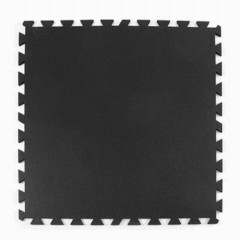

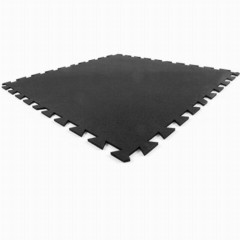

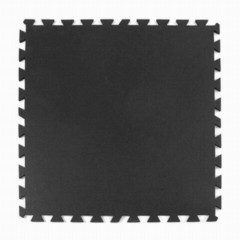

Interlocking or Straight Edge

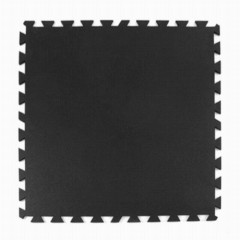

Interlocking 3x3 rubber floor tiles have a puzzle style edge that simplifies connecting adjacent tiles. You just pop the tabs on one tile into the slots on the adjacent tile. You don’t need glue to keep them connected, even when they’re under stress.

Straight edge tiles slide tightly against adjacent tiles without directly connecting to each other. If the tiles will be under stress, you might need to glue them to the subfloor to ensure a secure fit. Some straight edge mats have a beveled edge. You can reduce the trip hazard when you place the beveled edges around the exterior of the layout.

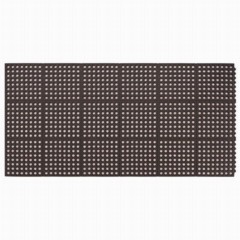

Solid or Perforated Holes

Solid surface rubber mats work best for those who need anti-fatigue properties and maximum durability for home gyms, commercial gyms, and fitness centers.

In areas where the mats will have exposure to water or spills, we offer perforated rubber mats. These mats have small holes in them that allow liquid to drain through to the subfloor and reach the floor drain, if you have one. The perforated rubber mats provide a sure footing even when they’re wet. They offer the same anti-fatigue capabilities as solid rubber mats.

Thickness Options

Our 3x3 rubber floor tiles are available in multiple thickness measurements. The most common options include:

- 1/4 of an inch

- 5/16 of an inch (8 mm)

- 3/8 of an inch

- 2/5 of an inch (10 mm)

- 15/32 of an inch (12 mm)

- 1/2 of an inch

- 5/8 of an inch

- 3/4 of an inch

Thicker 3x3 rubber flooring tiles provide greater protection for the subfloor when using large barbells or supporting heavy equipment. Thinner tiles are better for general workouts or lightweight exercise equipment.

Thicker mats absorb noise better than thinner mats. However, the thin rubber tiles weigh less and are easier to handle and cut during installation than thicker rubber tiles.

Features and Benefits for 3x3 Rubber Floor Tiles

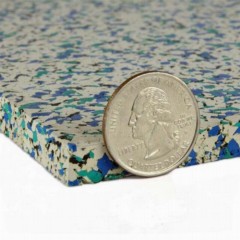

One of the biggest benefits of our 3x3 rubber floor tiles is that they often consist of between 50% and 100% of recycled rubber. You also could select rubber floor tiles that use virgin EPDM (ethylene propylene diene monomer) for a higher cost, but the recycled rubber’s performance and quality is as good as virgin EPDM.

Rubber is a naturally grippy material, helping you maintain your footing even when it’s wet. It doesn’t require any texture patterns across the surface for traction, although some models do have a gritty texture.

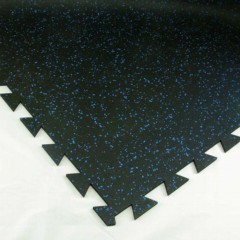

Although most 3x3 rubber tiles are black, some models have color flecks added to the black base color. Other colors are possible as the base color, including:

- Blue

- Gold

- Gray

- Green

- Orange

- Purple

- Red

Where to Use a 3x3 Rubber Mat

Some of the most common places people will install our 3x3 rubber mat products include:

- Under exercise equipment

- Spin class rooms

- Weightlifting areas

- Home gyms

- Commercial kitchen

- Dishwashing station

- Animal wash bay

- Factory line

3x3 Rubber Floor Tiles Q&A

Where can I find good quality 3x3 rubber tiles for a gym floor?

Our 3x3 Geneva Rubber Tiles are a

good quality 3x3 rubber tile for a gym floor. These tiles use an interlocking edge for a secure connection. They can stand up to rough treatment without showing wear, making them ideal for home gyms, commercial gyms, and weight rooms. They absorb noise and protect the subfloor from impact.

How do you cut rubber gym mats and tiles?

To successfully

cut rubber gym mats and tiles, hold a straight edge on the cut line and use a utility knife. Score the material repeatedly on the cut line. If you place a piece of scrap 2x4 lumber under the mat directly beneath the cut line, the rubber will slowly pull apart along the cut line, simplifying cutting the material.

What are the major differences between rubber floor tiles and rubber flooring rolls?

The primary

differences between rubber floor tiles and rolls are that the interlocking tiles are easier to install and don’t require glue to connect the edges. A roll of rubber may need glue or tape to hold it down, and its weight makes installation a little more challenging. Rolls are usually cheaper per square foot and thinner than rubber tiles.

How do you install interlocking rubber floor tiles on concrete?

To install interlocking rubber tiles over concrete, clean the concrete well. Then start in the middle of the room with a tile and work outward. When you reach a wall or obstacle, cut the puzzle-style edges off the tile to fit within 1/4 to 1/8 of an inch of the obstacle or wall (to allow for expansion).

What are some different interlocking rubber tiles?

At Greatmats, we carry quite a few

different interlocking rubber tile options. Our tiles vary quite a bit in thickness, ranging from about 1/4 of an inch to about 3/4 of an inch. For special use cases, like a playground or a weightlifting workout, thicker models are available. We also offer a range of color options, from black to black with color flecks to non-black colors.

$15987 /Tile You Save 15%$16.85/sqftShop$15370 /Tile You Save 14%$15.37/sqftShop$5540 /Tile You Save 20%$6.72/sqftShop$3246 /Mat You Save 20%$3.61/sqftShips Out in 11-14 Working DaysShop$17606 /Tile You Save 15%$18.55/sqftShop$3075 /Tile You Save 20%$3.73/sqftShips Out in 3-5 Working Days SustainableShop$4303 /Mat You Save 20%$4.78/sqftShips Out in 11-14 Working DaysShop$3458 /Tile You Save 19%$4.19/sqftShop$8222 /Tile You Save 19%$9.97/sqftShop$16986 /Tile You Save 15%$16.99/sqftShop$5090 /Tile You Save 19%$6.17/sqftShop$4656 /Tile You Save 20%$5.64/sqftShop$7534 /Tile You Save 19%$9.13/sqftShop$3577 /Tile You Save 19%$4.34/sqftShips Out in 3-5 Working Days SustainableShop$3207 /Tile You Save 20%$3.89/sqftShop

$15987 /Tile You Save 15%$16.85/sqftShop$15370 /Tile You Save 14%$15.37/sqftShop$5540 /Tile You Save 20%$6.72/sqftShop$3246 /Mat You Save 20%$3.61/sqftShips Out in 11-14 Working DaysShop$17606 /Tile You Save 15%$18.55/sqftShop$3075 /Tile You Save 20%$3.73/sqftShips Out in 3-5 Working Days SustainableShop$4303 /Mat You Save 20%$4.78/sqftShips Out in 11-14 Working DaysShop$3458 /Tile You Save 19%$4.19/sqftShop$8222 /Tile You Save 19%$9.97/sqftShop$16986 /Tile You Save 15%$16.99/sqftShop$5090 /Tile You Save 19%$6.17/sqftShop$4656 /Tile You Save 20%$5.64/sqftShop$7534 /Tile You Save 19%$9.13/sqftShop$3577 /Tile You Save 19%$4.34/sqftShips Out in 3-5 Working Days SustainableShop$3207 /Tile You Save 20%$3.89/sqftShop