Options for Wet Area Commercial Slip-Resistant Flooring

Working in an industrial area, commercial kitchen, or factory setting can be challenging enough on its own. If these work areas are also constantly wet, though, it can become downright dangerous. When you install commercial slip-resistant flooring from Greatmats, you can make the workspace more comfortable and safer. We have a wide range of flooring styles, colors, materials, and sizes to improve safety with our non-slip and cushioned flooring. Many of these anti-slip floor tiles for a commercial facility also provide anti-fatigue capabilities.

Types of Commercial Non-Slip Flooring for Wet Rooms

We offer three different types of commercial non-slip flooring, including:

- Matting rolls: Matting rolls can cover a long runway of space along an aisle or assembly line.

- Mats: Mats are pre-cut to a particular size, making it easy to cover a space in front of a workstation.

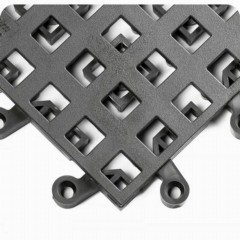

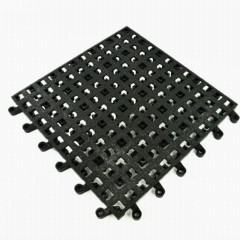

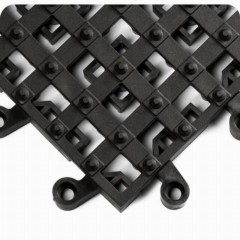

- Tiles: Interlocking tiles are a great option for creating a unique coverage shape and area.

Materials for Commercial Slip-Resistant Flooring

Select among a variety of materials in our commercial flooring for wet areas products.

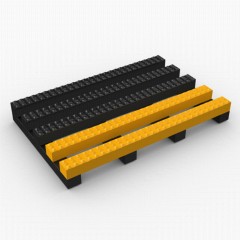

PVC Plastic

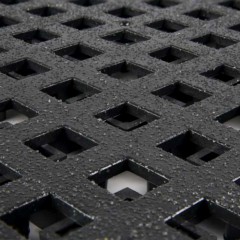

PVC plastic is the most common type of commercial slip-resistant flooring. It can withstand environments with constant moisture while retaining its grippy surface. Holes in the PVC allow the water to drain away, rather than sitting on the surface.

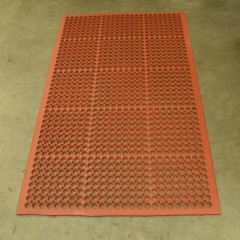

Rubber

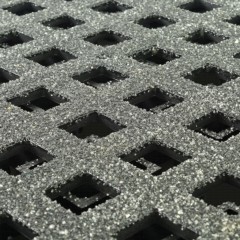

Rubber is a highly durable flooring that won’t absorb water. It is a naturally grippy material that prevents slipping. In a kitchen environment, some types of rubber mats can withstand oils and chemicals.

Vinyl

Vinyl floors naturally have slip resistance, ensuring a sturdy footing for commercial and industrial areas.

Features and Benefits of Industrial Non-Slip Flooring for Wet Areas

Our commercial kitchen floor tiles that are non-slip offer a wide range of benefits, including:

- Slip resistance

- Moisture resistance

- Durability

- Comfort underfoot

- Perforations for drainage

- Raised surface texture

- Anti-fatigue cushioning

- Some models withstand chemicals, oils, and acids

- Resists formation of mold and mildew

- Easy to clean and maintain

Where to Use Commercial Slip-Resistant Flooring

You can use our industrial non-slip flooring in a variety of locations, including:

- Industrial area

- Commercial kitchen

- Restaurant kitchen

- Food prep area

- Assembly line

- Factory setting

- Manufacturing area

- Workstation

- Areas with floor drains

- Damp walkway or aisle

Wet Room Commercial Slip-Resistant Flooring Q&A

What are the safest indoor waterpark floors?

The

safest indoor waterpark floors should provide comfort for people walking in bare feet and prevent the growth of mold and mildew in constantly damp conditions. Some floors provide fall protection and anti-slip capabilities that significantly outperform bare concrete. Soft PVC plastic is often the best material for flooring at indoor waterparks.

What is an anti-slip mat and what are the best products?

An

anti-slip mat is a type of flooring that helps people maintain a sure footing, even in wet conditions. The best products to use as anti-slip mats often consist of PVC plastic, rubber, or rubber composites. These materials won’t absorb water and have a naturally grippy surface texture.

What are some top drainage mats and matting for commercial floors?

Some of the

top drainage mats for commercial floors include the

SuperFoam Perforated Anti-Fatigue Mat and the

WorkStep Black Mat. The drainage holes in these mats let water move to the subfloor and toward a floor drain. They often have anti-slip and anti-fatigue capabilities.

What is the best walk-in cooler and freezer floor matting?

The

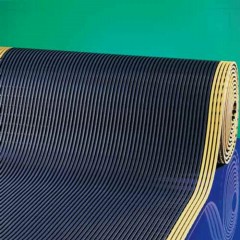

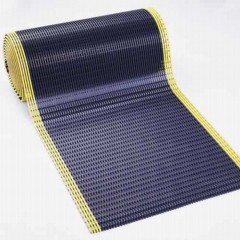

best walk-in cooler and freezer floor matting provides a safe place to walk where ice may appear on the floor. These mats have an anti-slip texture to yield a sure footing regardless of the temperatures. Some of our most popular choices are the

Vynagrip Heavy Duty Industrial Matting and the

Firmagrip Industrial Matting.

Where would you need slip- or skid-resistant flooring?

The best

areas to use slip-resistant or skid-resistant flooring include:

- Patios

- Decks

- Locker rooms

- Around pools

- Splash pads

- Showers

- Bathrooms

- Saunas

- Hot tubs

- Docks

- Boats

- Greenhouses

- Industrial environments

- Factories

- Walk-in freezers

- Commercial kitchens

- Assisted-living facilities

- Nursing homes

- Dog agility spaces

$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$38295 /Carton You Save 36%$17.02/sqftShips Out in 4-6 Working Days SustainableShop$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$38295 /Carton You Save 36%$17.02/sqftShips Out in 4-6 Working Days SustainableShop$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$9699 /Mat You Save 20%$3.23/sqftShips Out in 11-14 Working DaysShop

$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$38295 /Carton You Save 36%$17.02/sqftShips Out in 4-6 Working Days SustainableShop$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$38295 /Carton You Save 36%$17.02/sqftShips Out in 4-6 Working Days SustainableShop$24326 /Carton You Save 36%$10.81/sqftShips Out in 4-6 Working Days SustainableShop$9699 /Mat You Save 20%$3.23/sqftShips Out in 11-14 Working DaysShop