Portable Dance Floor Seamless Wood Grain Cam Lock 1/2 Inch x 3x4 Ft.

Be the first to review this product

$619.20/each

Save 9%

$51.60/sqft

Reg: $688.00/each

Handling Time Estimate: 4-6 Weeks

- Beautiful wood grain designs

- Sturdy Douglas Fir plywood base

- Secure and fast Cam-lock fastening to connect panels

- See More Details

- Beautiful wood grain designs

- Sturdy Douglas Fir plywood base

- Secure and fast Cam-lock fastening to connect panels

- Large 3x4 foot panels

- Provides a superior event dance experience

- Create an elegant dance floor

- Perfect for event and wedding venues

- Only one tool needed for assembly

- Wedding Dance Floor

- Portable Dance Floor

- Banquet Flooring

- Event Center Flooring

- Hotel Ballrooms

NOTE: This item is a custom order and is not returnable.

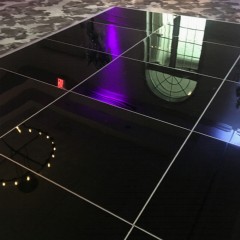

Seamless Portable Dance Flooring

This Seamless Portable Dance Floor combines a durable, strong Douglas Fir plywood base with a seamless vinyl dancing surface for a beautiful temporary dance floor solution. This is an ideal portable or temporary dance floor solution for event rental companies, wedding venues, event centers, hotel ballrooms, and conference centers.

The continuous vinyl panel is a unique product on the market that offers a larger seamless dancing area, replacing individual 12 x 12 tiles. Multiple panel sizes are available in 3x3 feet or 3x4 feet.

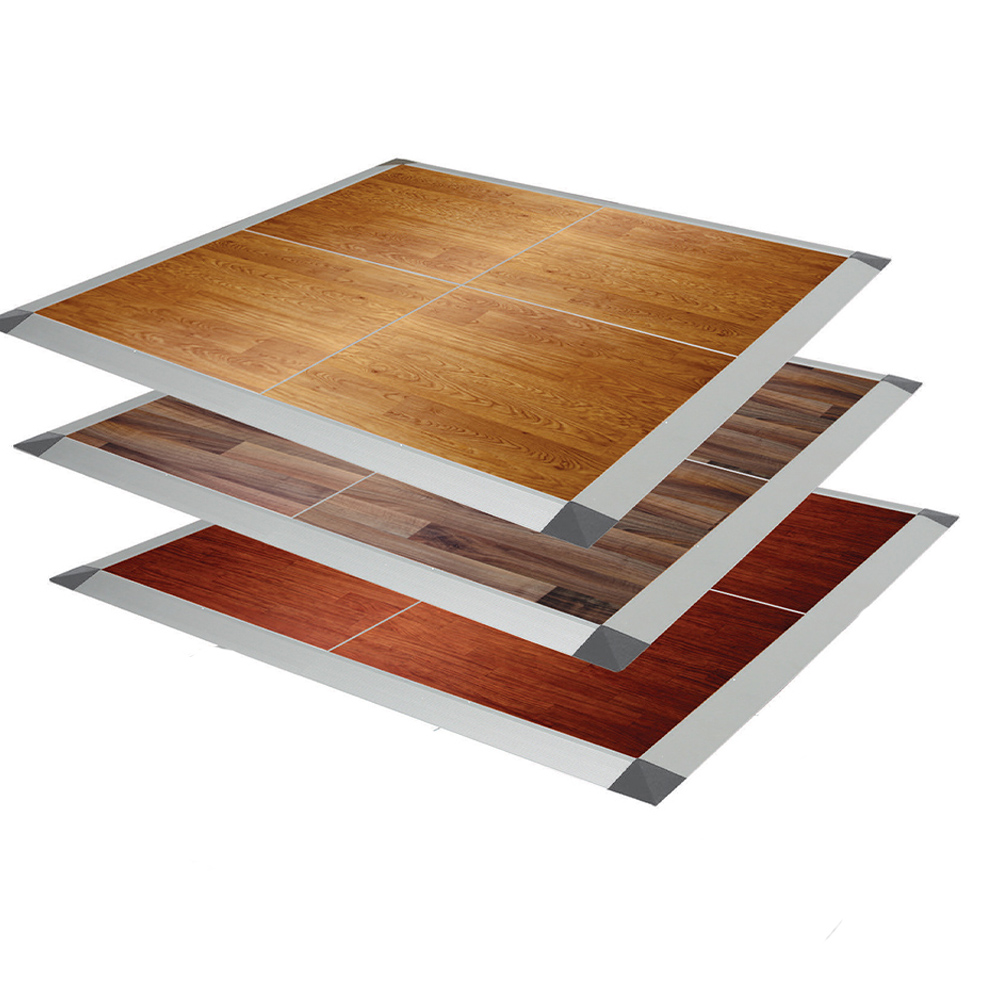

Choose from beautiful wood grain colors to match your venue's aesthetic.

- American Plank: This warm and inviting color exudes timeless elegance, reminiscent of rustic charm and classic American craftsmanship.

- Dark Oak: Make a bold statement with the rich and luxurious tones of Dark Oak.

- Dark Walnut: Embrace the allure of Dark Walnut, a captivating blend of deep browns and subtle undertones.

- Elegant Oak: This graceful hue combines soft, neutral tones with delicate grain patterns, creating a sense of understated luxury.

- Tropical Beech: With its radiant tones and inviting warmth, Tropical Beech infuses your wedding dance floor with a sense of airy elegance.

Easy DIY Installation

The easy cam-lock fastening of the panels reduces installation and take down time as well as provides a solid and secure dance floor base. Use a hex key tool to turn the Cam-lock fasteners.

Anodized aluminum border trim offers an upscale feel to your completed dance floor. Optional soft corners are available that provide protection from sharp corners.

The panels have a semi-gloss finish but can be waxed and buffed or polished to a gloss finish if desired. Please review the maintenance details required for waxing and polishing recommendations.

Maintenance

Push broom or dry mop. Spot clean difficult stains or spills. Use all-purpose floor cleaner and mop with hot water.

Waxing and Polishing Procedures and Maintenance can be found in PDF Documents.

Disclaimer

Any furniture placed on the panels should have adequate floor protectors to prevent indentations or damage. Care must be taken when moving furniture or other heavy objects over the panels. Do not slide or wheel heavy objects across the floor. Failure to use adequate precautions may result in scratches, cuts, or other severe damage to the floor covering.

Prolonged exposure to direct sunlight is likely to cause discoloration of the seamless vinyl surfaces on our portable dance floor products. Minimizing UV light exposure will extend the life of your dance floor.

Shipping

Ships shrink wrapped on pallets.

Please review our shipping disclaimer.

| SKU# | 4DFPANEL-CAM |

| In Stock | Yes |

| Product Type | Tile |

| Material Type | Vinyl |

| Product Edging | Straight |

| Thickness | 1/2 inch |

| Width | 3.00 feet |

| Length | 4.00 feet |

| SF per Item | 12.00 |

| Weight | 48.00 lbs |

| Packaging | Shrink Wrapped on Pallets |

| Non Absorbent | No |

| Special Adhesives | No |

| Interlock Loss | 0.00 feet |

| Interlocking Connections | Yes |

| Made In | USA |

| Surface Finish | Smooth |

| Surface Design | Wood grain |

| Installation Method | Cam lock |

| UV Treated | No |

| Reversible | No |

| Border Strips Included | No |

| Manufacturer Warranty | 5 Year Limited, 1 Year Rental Companies |