What Is The Difference Between ESD Matting & Switchboard Matting?

Related Product: SkyStep ESD Rubber Anti-Fatigue Mat 5/8 Inch x 3x5 Ft.

ESD vs. Switchboard Matting

Both ESD and switchboard matting are used to reduce static shock, but the way that they reduce that shock is different. As a result, ESD mats are suitable for certain applications, while you’ll want to choose switchboard mats for different situations.

The main difference between ESD and switchboard matting lies in their conductivity. ESD is conductive matting, which helps protect sensitive electronic components. In contrast, switchboard matting is nonconductive and is specifically designed to protect workers against life-threatening electric shock.

How ESD Matting Works

ESD matting helps protect electronic components and machines, which could be damaged or destroyed by static shock. Also called static dissipative or conductive matting, ESD matting reduces the resistance of electricity, which helps it to pass through the electronic component that a worker is handling. Since ESD matting is conductive, it helps channel the static charge through the user into the mat. From there, a grounding cord channels the static away to a point where it’s grounded, safely transferring it away from the vulnerable component or machine.

If that same worker wasn’t standing on ESD matting, the static charge could rebound back through their body, uncontrolled. The electronic component would function as a ground, and the static charge could destroy it.

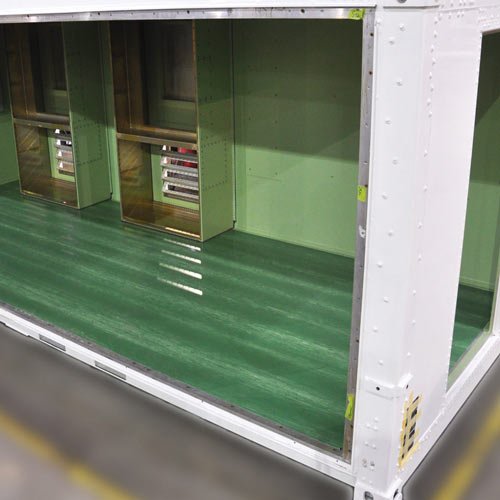

ESD matting is often used in settings where workers handle electrostatically sensitive components, including computer server rooms, cleanrooms, assembly lines, medical and dental offices, electronics manufacturing lines, and computer repair shops.

How Switchboard Matting Works

While ESD matting channels static electricity safely away from a vulnerable component, switchboard matting is designed to help protect people from electrocution. This nonconductive matting insulates a worker, protecting them from any electrical current and helping prevent severe burns or even death.

Switchboard matting acts as a barrier between a worker and the ground, stopping electricity from traveling through the worker.

This matting is used in dry environments when workers are exposed to high-voltage electrical equipment. It can be used around fuse boxes, transformers, circuit breaker rooms, metering rooms, and more. It’s frequently used in industrial work zones and any areas where workers will be servicing equipment.

In addition to preventing electricity from traveling through a worker and into the ground, which could result in death, switchboard matting often features slip resistance to contribute to worker safety. The Occupational Safety and Health Administration (OSHA) requires employers to maintain safe working environments in areas with electrical hazards, so installing switchboard matting is often a required and necessary step.

Choosing the Best ESD Matting

At Greatmats, we carry ESD matting made of vinyl, rubber, rubber/foam, vinyl-bonded foam, and PVC plastic. The matting is available in numerous sizes, too. Interlocking tiles are easy to install and allow you to create desired coverage sizes. Our small mats are perfect for individual workstations or desks, while rolls give you more coverage that’s suitable for rooms or assembly lines.

These ESD mats offer highly desirable features, including a dry-lay installation that allows you to easily remove them if needed. They’re crafted with cushioned materials, which can help reduce body fatigue, contributing to worker comfort. The mats are designed for durability, and they help protect your electrical equipment. The mats are also available in numerous finishes, including those that help maximize traction, so you’ll have plenty of options when choosing the best mat for your workspace.

Choosing the Best Switchboard Matting

We offer two types of switchboard matting at Greatmats. Corrugated runner switchboard mats offer generous coverage, and they’re ideal for large-scale installations. These mats feature a dielectric strength of up to 30,000 volts, offering excellent protection to workers.

Our vinyl roll switchboard mats feature a smooth surface and are available in multiple dimensions. They’re created for high-voltage areas and have an electrically insulated surface.

Switchboard mats feature many valuable qualities. They’re crafted with a fire-retardant surface for safety, and some products are UV-resistant, too. Anti-slip textures are available for enhanced safety, and some products also have a stylish design. When choosing your matting, make sure that you select a mat with an appropriate voltage rating for your workplace. Mats vary in their levels of protection and certifications.