What Is the Benefit of Hand Scraped Hardwood Flooring?

Related Product: Hampton Suite Engineered Hardwood Flooring 26 Sq Ft per Carton

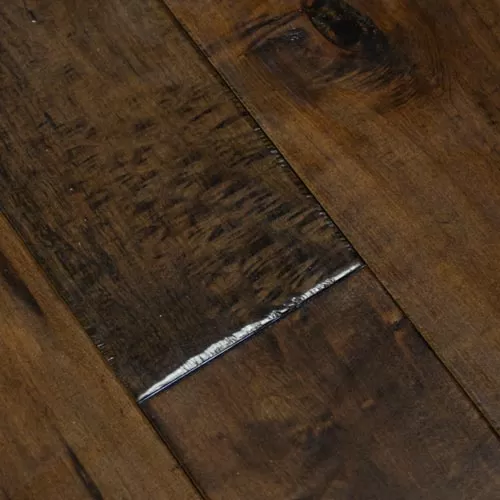

Hand scraping removed undulations and irregularities in the wood, creating a material that’s suitable for use as a floor, where imperfections and uneven thicknesses might result in a tripping hazard.

Once machines began sanding and finishing wood planks for flooring, the art of hand-scraped hardwood flooring nearly disappeared. Investing the time and craftsmanship required to create the hand scraped look became limited to the most expensive flooring installs, where customers were seeking a unique and rustic design with character.

Another benefit of hand scraped hardwood flooring is the durability it offers, while requiring very little maintenance compared to other hardwoods.

For those who don’t have the budget to afford it, though, other options are available that provide a similar look and level of performance at a fraction of the price, such as engineered hardwood.

What Are Some Less Expensive Substitutes for Hand Scraped Hardwood Flooring?

Although it’s difficult to recreate the look of hand scraped hardwood flooring with a machine, it’s not impossible. Some types of faux wood grain floorings consisting of laminate or vinyl can give the appearance of the grooves and hand scraped textures in the original hardwood designs.However, for the best approximations of hand scraped hardwood flooring at a lower price, consider engineered hardwood. You can select from multiple stains and types of hardwood in the veneer layer with these products. Some of the best options include:

Hamption Suite Engineered Hardwood Flooring

The Hampton Suite Engineered Hardwood Flooring uses a 2 mm thick veneer layer, giving it the ability to stand up to wear and tear from regular foot traffic. The veneer layer has a hand scraped appearance that approximates vintage wood. It makes use of 7.5-inch wide planks along with varying lengths between 11 inches and 83 inches, which helps to create the most realistic layout during the installation. Its available colors and patterns include: Amber Ale maple, Brandy Wine maple, Cognac maple, Moonshine maple, Smoked Bourbon maple, Stout maple, and Whiskey maple.

Porter Hill Engineered Hardwood Flooring

For a highly realistic look in the engineered hardwood, consider the Porter Hill Engineered Hardwood Flooring. It has a look of hand scraped flooring in the 2 mm veneer layer, along with filled knots and beveled edges. The planks measure 7.5 inches in width and have varying lengths between 11 inches and 83 inches for a realistic look in the layout. The finish carries a 35-year warranty, while the actual engineered hardwood planks have a limited lifetime manufacturer's structural warranty. The available colors include: Amber, Bronze, Cinnamon, Deep Brown, Flaxen, and Sandy Beach.

Florence Green Engineered Hardwood Flooring

For a type of engineered hardwood plank that has varying widths, allowing it to closely approximate the look of certain types of vintage flooring, consider the Florence Green Engineered Hardwood Flooring product. Customers receive random plank widths of 4.5 inches, 6 inches, or 7.5 inches. Varying plank lengths are available too, ranging from 11 inches to 72 inches. The Sunset maple finish in the 2 mm wear layer will provide long lasting performance, as the planks will continue to look new, even when used in locations with heavy foot traffic.

What Is Engineered Hardwood?

Like solid hardwood, engineered hardwood consists of real wood. However, the engineered hardwood has plywood layers as the base material, while using a thin veneer layer of the actual hardwood, such as oak, hickory, or maple, attached to the top of the plywood. Solid hardwood flooring comes from a single piece of wood.Because engineered hardwood uses the plywood base, manufacturers can offer it for a lower cost per square foot of coverage than real hardwood.

Additionally, engineered hardwood will not shrink and expand with changes in the humidity and temperature levels in the building. Because of the manufacturing process employed with engineered hardwood, it’s subject to heating and pressuring during the construction, leaving it able to withstand environmental changes. Some other hand scraped hardwood flooring may suffer from expansion and shrinking issues.