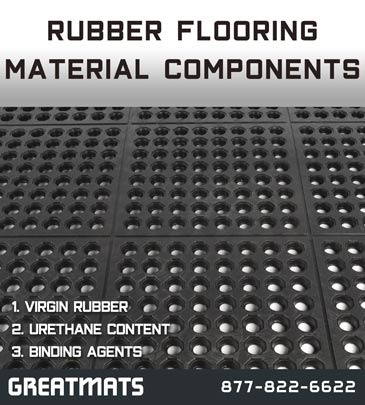

Rubber Flooring Material Compounds

Related Product: Rubber Flooring Rolls Geneva 8 mm Black Per SF

Rubber Compounds

When it comes to rubber flooring material, there are a number of major components involved. Though all rubber products require a number of different elements, a lot of flooring is made predominately of virgin or natural rubber. Some rubber flooring products contain urethane. It is worth noting here that urethane is one of the 14 member titles that chemists use to classify rubber. So it's not a foreign product, it is a type of rubber. It's not the only component mixed with natural or synthetic rubber to create rubber flooring but it is a very popular one so we'll contrast products without it to those than contain it.Because, at Greatmats, we deal in both types of products, we tend to not get caught up in which rubber flooring product is better than the other. Having sold rubber flooring since 1999, we've seen firsthand that there are specific advantages to each type. Understanding the differences between these two products will help you to determine which flooring product is best for your application.

Typically, people tend to think that natural, or virgin, rubber is the superior product. It doesn't contain recycled materials and tends to cost more than rubber created with a urethane mix. These rubber flooring products tend to be softer and more pliable which makes for a more comfortable standing surface. It also has a better elastic memory so it tends to hold its shape better. It is for these reasons that most people consider natural rubber superior to rubber made with urethane.

However, what urethane rubber lacks in softness and pliability it makes up for in toughness. Urethane manufactured rubber floors are more scratch-resistant than natural rubber ones. Urethane (or polyurethane), when mixed with rubber, creates a harder product. This flooring tends to be less expensive because it often contains recycled rubber (often made directly from recycled tires) so it is also environmentally friendly. The quality of the rubber compound in rubber flooring, or other rubber products, depends not only on the rubber and urethane but also the added components that are added. There are some places that will add a variety of different things into the mix. Some countries even add used motor oil because it is an easy way to dispose of it. This is never a concern with Greatmats products. All our urethane rubber tiles and rolls are made in the United States and are held to the highest standards in urethane flooring.

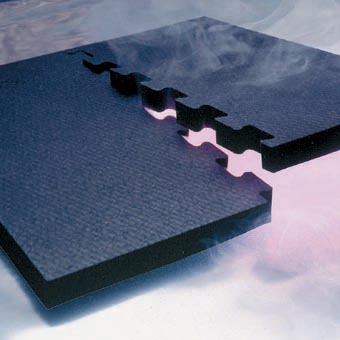

One of the most common complaints regarding urethane over natural rubber is the rubber smell that accompany those products. However, this is a misconception. The type of rubber used in the manufacturing process is not the cause of the rubber odor. The cause is the binder used in the vulcanization process. Vulcanization is a process that gives rubber its elasticity and ''bounce back'' capability. Rubber in its natural state is brittle and much less resistant to heat and cold. In most cases where the rubber odor is strong, the binding agent used in the process was usually a sulfur-based agent. At Greatmats, we have flooring that has been manufactured with sulfur-based agents and flooring that has not. It is important that you understand which products have that odor and which do not. If your rubber flooring is for a stable or well ventilated warehouse, you may find that the less expensive, higher odor, flooring is the way to go. If you're putting it in a bedroom or basement exercise room, you will probably be better served going with a lower-smell option. Talk to your customer service representative to determine which type is best for your application.